Machine Center NC Rotary Table

Product Details

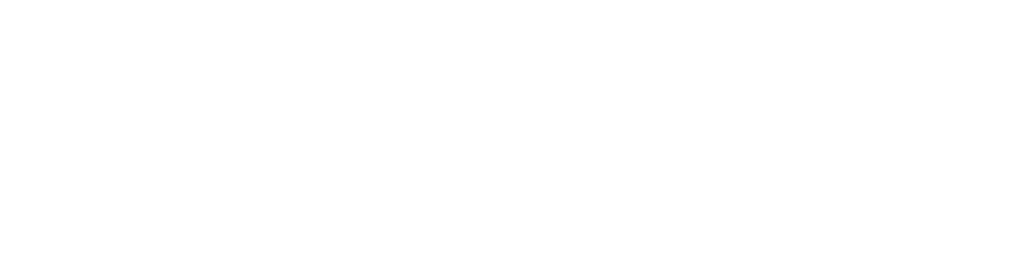

Model | CTB-125 |

Table Diameter [mm] | Φ125 |

Center Hole Diameter [mm] | Φ30 |

Through Hole Diameter [mm] | Φ22 |

T Slot Width [mm] | 12 H7 |

Center Height [mm] | 110 |

Guide Key Width [mm] | 14 H7 |

Min Increment | 0.001° |

Servo Motor | β4is, HG105 |

Gear Ratio | 1:48 |

Max R.P.M. [r.p.m.] | 62.5 |

Indexing Accuracy [sec] | 20 |

Repeatability [sec] | 4 |

Allowable Work Inertia [kg·m²] | 2 |

Locking Torque [kg/m] | 13 |

Locking Method [kg/cm²] | Pneumatic 6 |

Allowable Cutting Torque [kg/m] | 9 |

Net Weight [kg] | 35 |

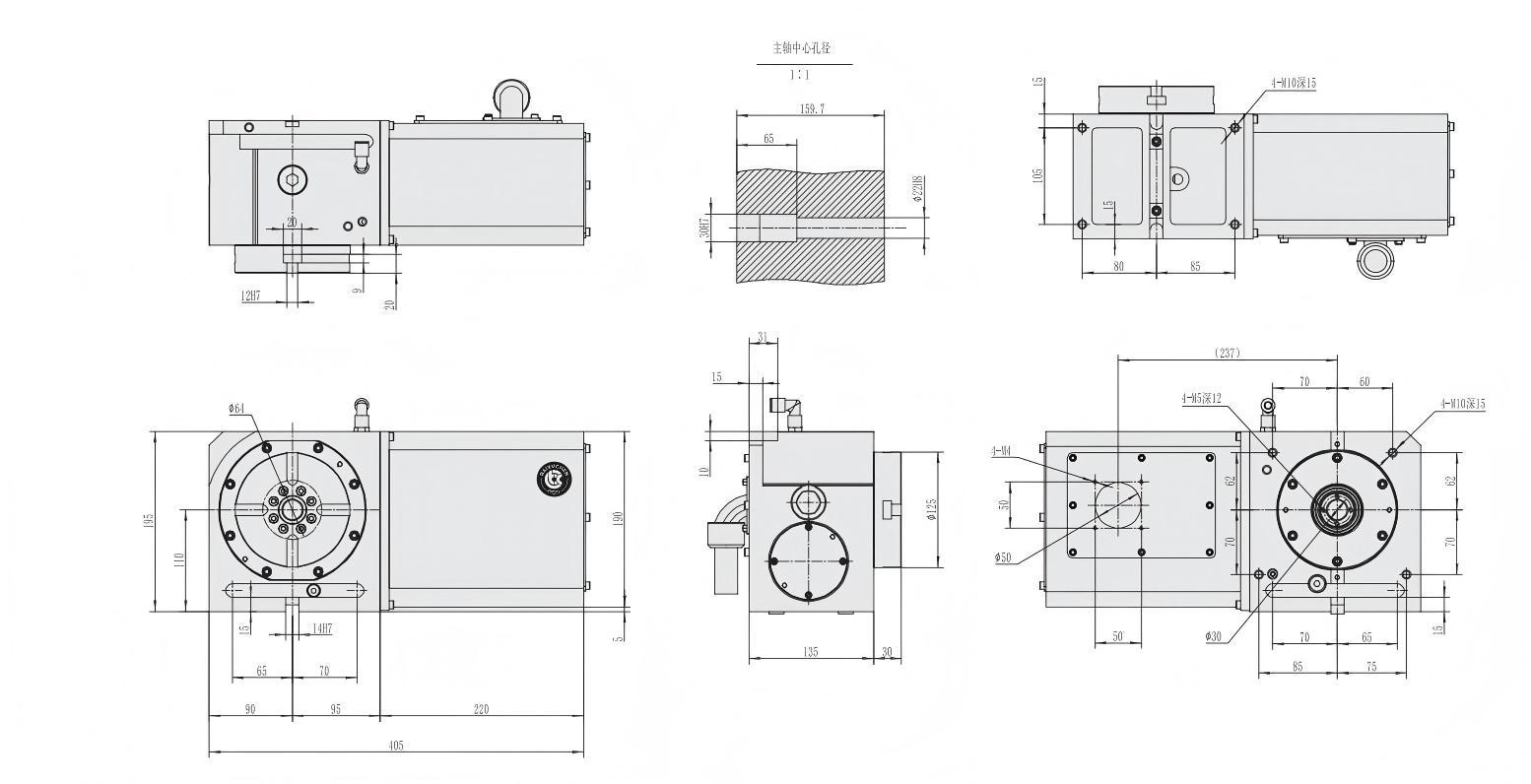

What is the benefits of a machine center NC rotary table?

It improves machining accuracy and efficiency by enabling multi-axis machining in one setup.

RELATED PRODUCTS

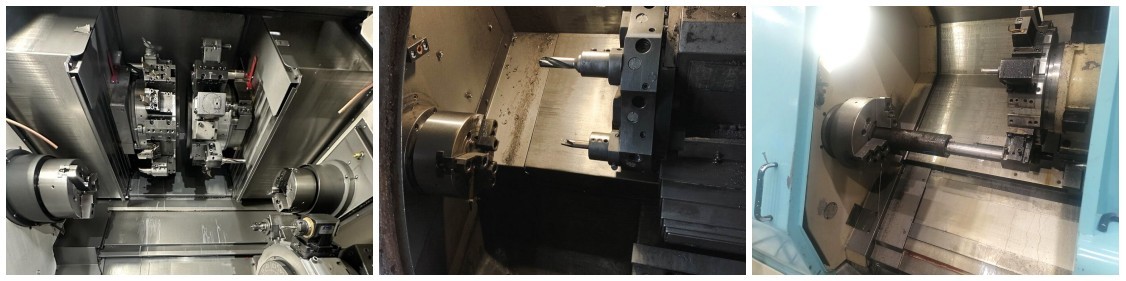

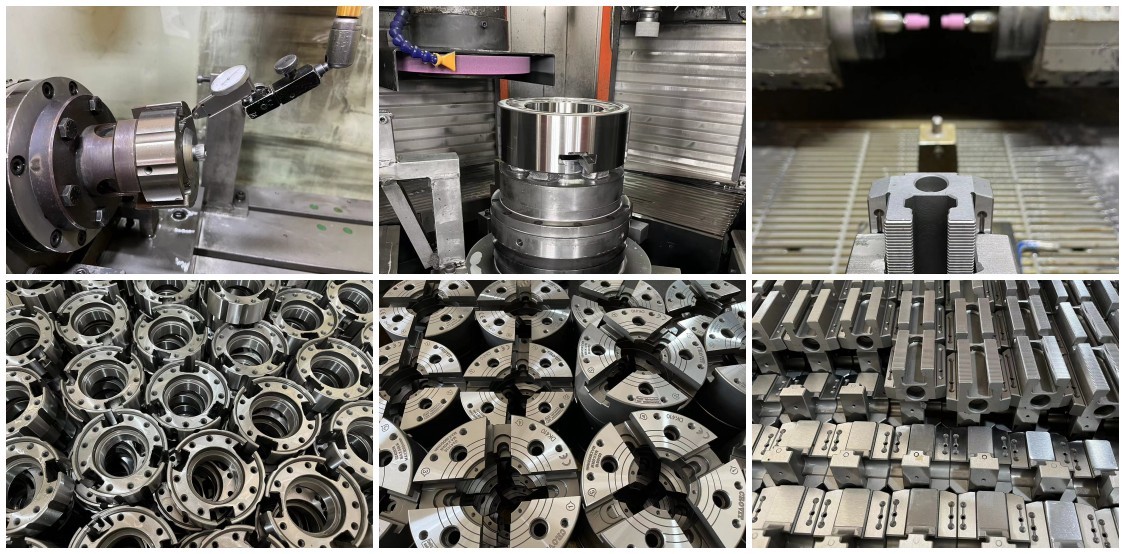

A hydraulic chuck tool holder is a type of tool holder that uses hydraulic pressure to securely hold cutting tools in place during machining operations, which is commonly used in CNC machining centers and other high-precision machining applications.

A hydraulic chuck is a type of workholding device commonly used on CNC lathes for securely gripping and holding workpieces during machining operations.

A power chuck is a type of workholding device commonly used in machining operations to securely grip and hold workpieces during turning, milling, drilling, or grinding processes. They are typically used on CNC lathes, machining centers, and other machine tools.

Hydraulic lathe chucks are commonly used in CNC lathes and other precision machining equipment to provide a strong and reliable grip on workpieces, ensuring stability and accuracy during turning, milling, drilling, or grinding processes.

GET A FREE QUOTE