12 Inch Power Chuck

Product Details

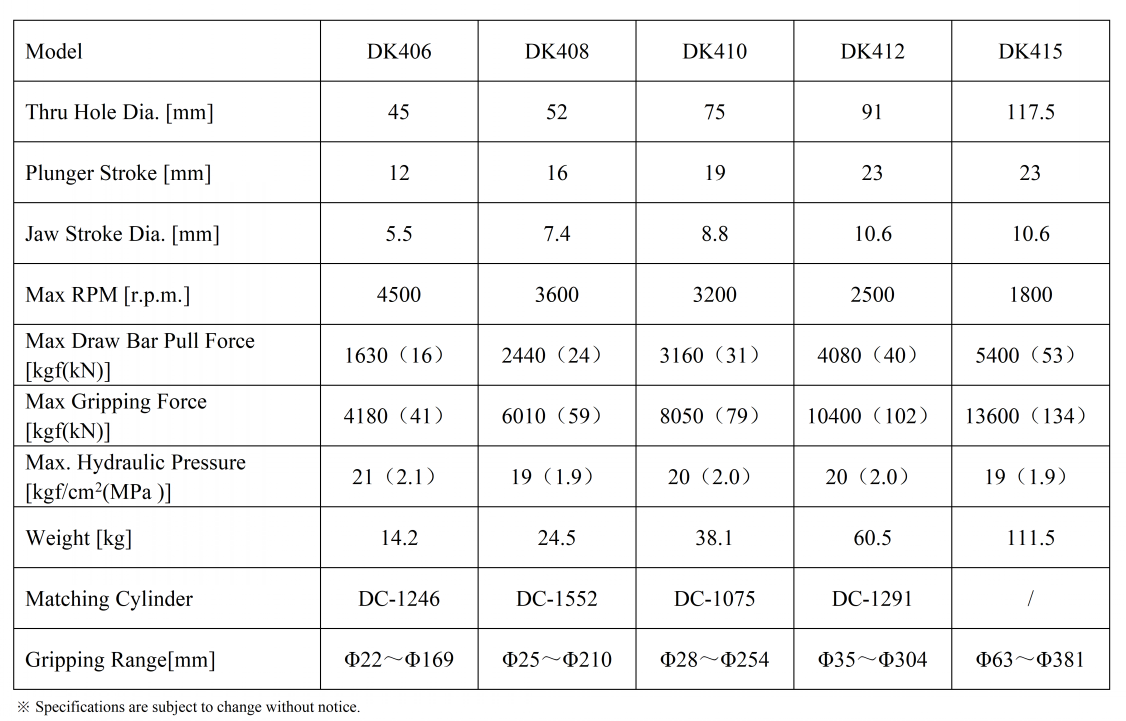

| Model | DK412 |

| Thru Hole Dia. [mm] | 91 |

| Plunger Stroke [mm] | 23 |

| Jaw Stroke Dia. [mm] | 10.6 |

| Max RPM [r.p.m.] | 2500 |

| Max Draw Bar Pull Force [kgf(kN)] | 4080(40) |

| Max Gripping Force [kgf(kN)] | 10400(102) |

| Max. Hydraulic Pressure [kgf/cm2(MPa )] | 20(2.0) |

| Weight [kg] | 60.5 |

| Matching Cylinder | DC-1291 |

| Gripping Range[mm] | Φ35~Φ304 |

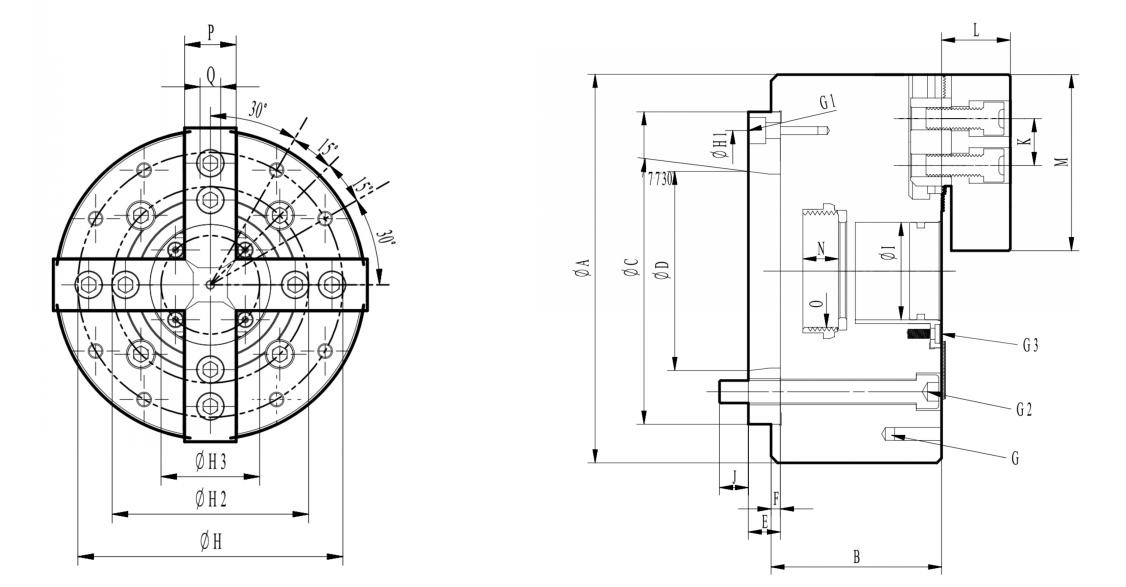

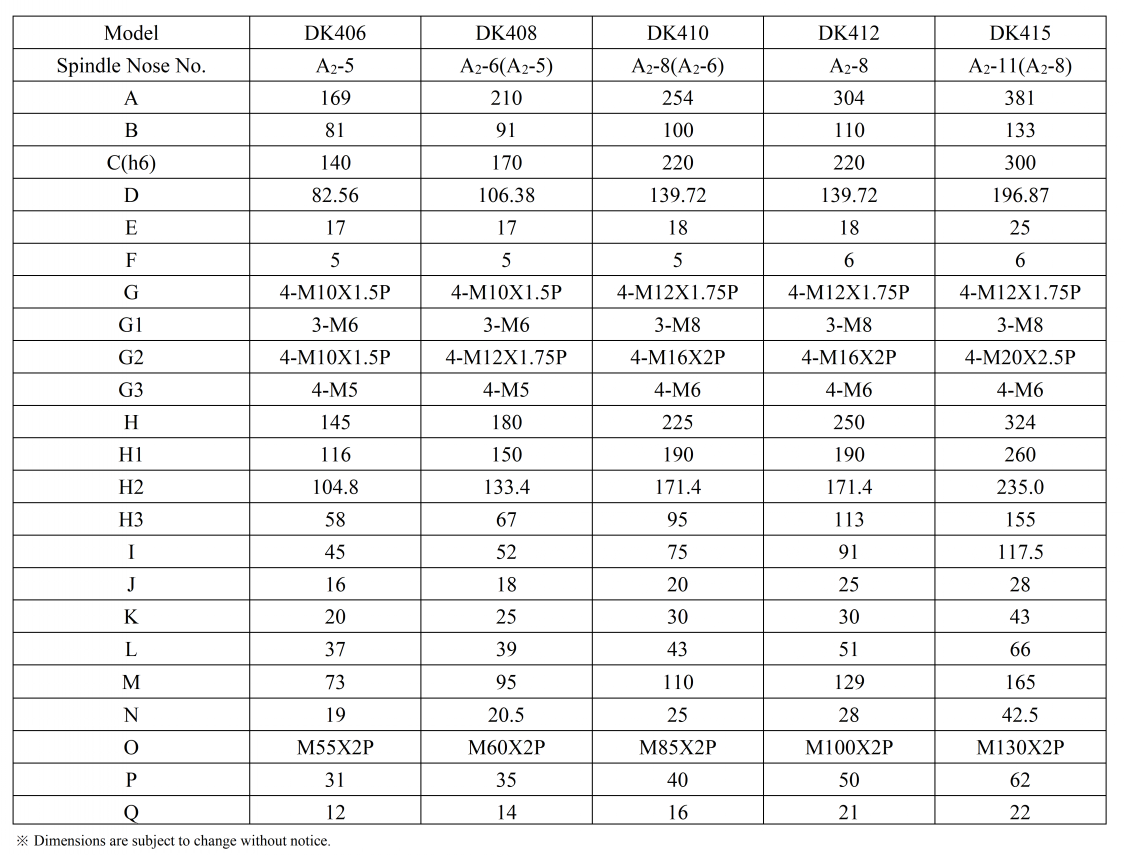

Model | DK412 |

Spindle Nose No. | A2-8 |

A | 304 |

B | 110 |

C(h6) | 220 |

D | 139.72 |

E | 18 |

F | 6 |

G | 4-M12X1.75P |

G1 | 3-M8 |

G2 | 4-M16X2P |

G3 | 4-M6 |

H | 250 |

H1 | 190 |

H2 | 171.4 |

H3 | 113 |

I | 91 |

J | 25 |

K | 30 |

L | 51 |

M | 129 |

N | 28 |

O | M100X2P |

P | 50 |

Q | 21 |

What are the advantages of using a power chuck over other types of workholding devices, such as collets or fixtures?

Some of the key advantages of using a power chuck include:

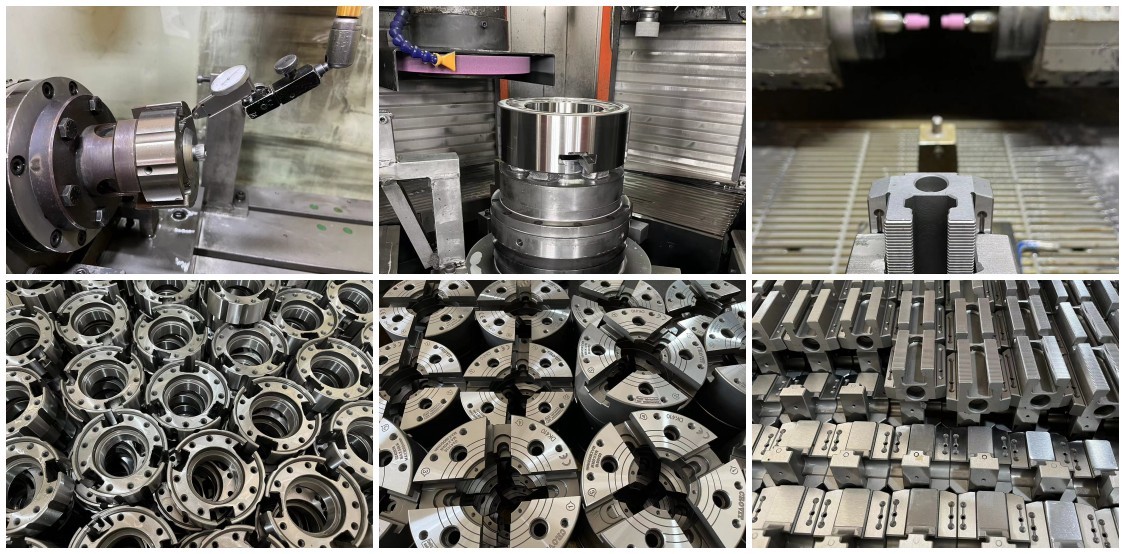

Versatility: Power chucks can be equipped with different jaw configurations to grip various types of workpieces.

Automation: Power chucks feature automated clamping and unclamping mechanisms that allow for quick and efficient workpiece changes. This automation reduces setup times and increases productivity compared to manual workholding devices like collets or fixtures.

Control: Power chucks offer precise control over the clamping force applied to the workpiece, ensuring secure and consistent gripping. Operators can adjust the clamping force based on the workpiece material and machining requirements, resulting in improved machining accuracy and part quality.

Repeatability: Power chucks provide high levels of repeatability in gripping the workpiece, allowing for consistent part positioning and machining accuracy. This repeatability is essential for achieving tight tolerances and maintaining part consistency in production runs.

Rigidity: Power chucks offer strong gripping force and rigidity, which helps minimize workpiece deflection and vibration during machining operations. This rigidity contributes to improved surface finish, dimensional accuracy, and overall machining performance.

Efficiency: Power chucks enable faster workpiece changes and setup times, reducing idle time and increasing machine utilization.

RELATED PRODUCTS

A hydraulic chuck tool holder is a type of tool holder that uses hydraulic pressure to securely hold cutting tools in place during machining operations, which is commonly used in CNC machining centers and other high-precision machining applications.

A hydraulic chuck is a type of workholding device commonly used on CNC lathes for securely gripping and holding workpieces during machining operations.

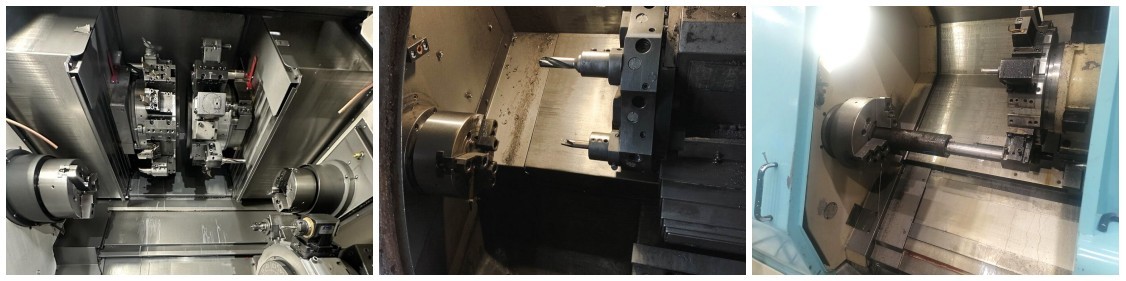

A power chuck is a type of workholding device commonly used in machining operations to securely grip and hold workpieces during turning, milling, drilling, or grinding processes. They are typically used on CNC lathes, machining centers, and other machine tools.

Hydraulic lathe chucks are commonly used in CNC lathes and other precision machining equipment to provide a strong and reliable grip on workpieces, ensuring stability and accuracy during turning, milling, drilling, or grinding processes.

GET A FREE QUOTE