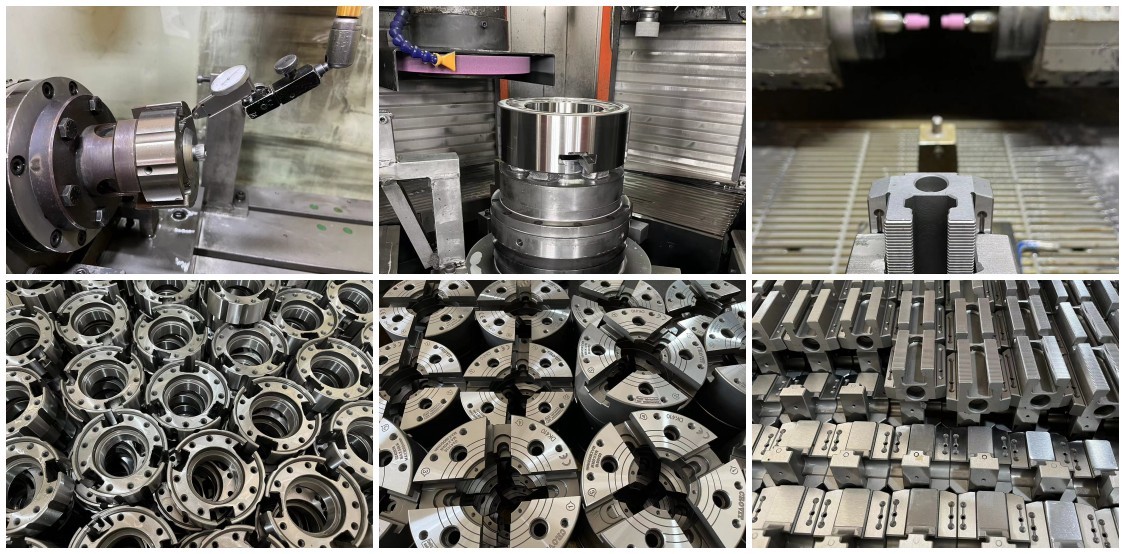

Large Hydraulic Chuck

Product Details

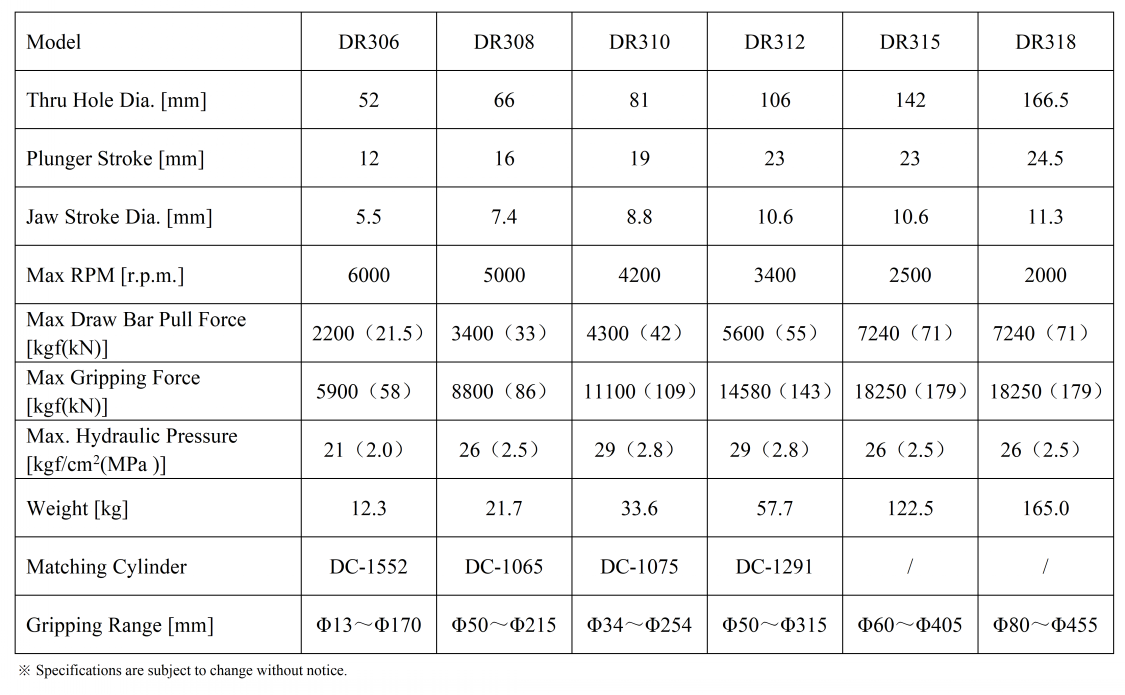

| Model | DR318 |

| Thru Hole Dia. [mm] | 166.5 |

| Plunger Stroke [mm] | 24.5 |

| Jaw Stroke Dia. [mm] | 11.3 |

| Max RPM [r.p.m.] | 2000 |

| Max Draw Bar Pull Force [kgf(kN)] | 7240(71) |

| Max Gripping Force [kgf(kN)] | 18250(179) |

| Max. Hydraulic Pressure [kgf/cm2(MPa )] | 26(2.5) |

| Weight [kg] | 165.0 |

| Matching Cylinder | / |

| Gripping Range [mm] | Φ80~Φ455 |

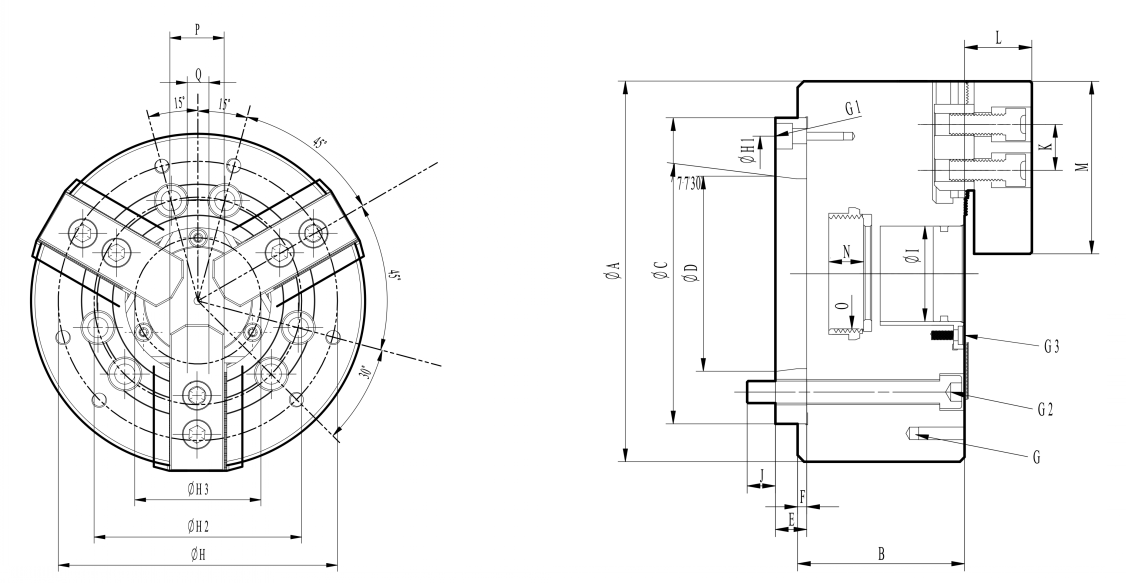

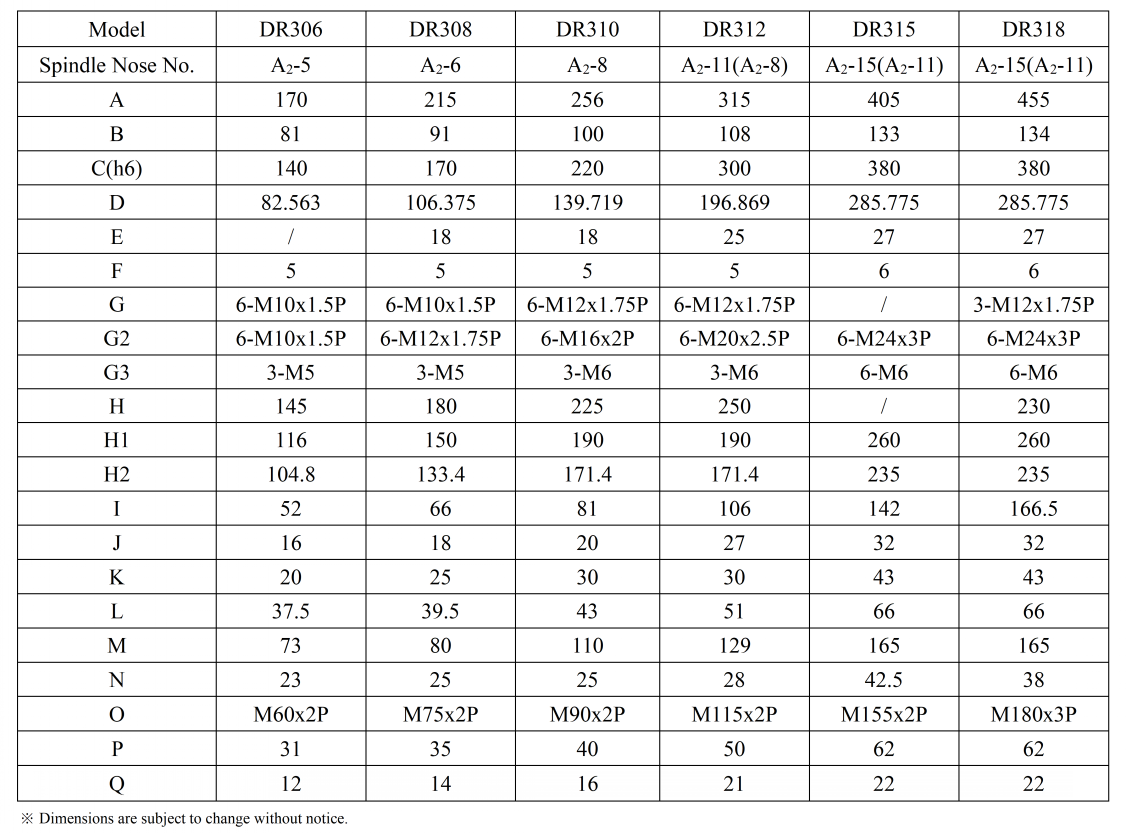

Model | DR318 |

Spindle Nose No. | A2-15(A2-11) |

A | 455 |

B | 134 |

C(h6) | 380 |

D | 285.775 |

E | 27 |

F | 6 |

G | 3-M12x1.75P |

G2 | 6-M24x3P |

G3 | 6-M6 |

H | 230 |

H1 | 260 |

H2 | 235 |

I | 166.5 |

J | 32 |

K | 43 |

L | 66 |

M | 165 |

N | 38 |

O | M180x3P |

P | 62 |

Q | 22 |

How long is the production time after I put the order?

Formal order: 20 working days after getting your prepayment;

Sample order: 7 working days after receiving your sample fees.

RELATED PRODUCTS

A hydraulic chuck tool holder is a type of tool holder that uses hydraulic pressure to securely hold cutting tools in place during machining operations, which is commonly used in CNC machining centers and other high-precision machining applications.

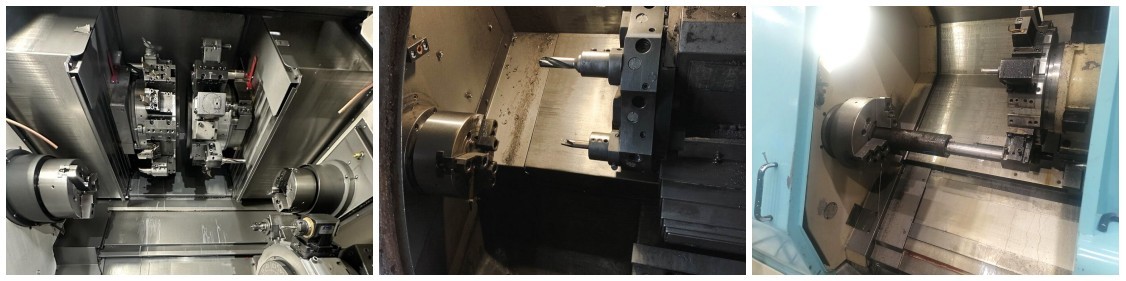

A hydraulic chuck is a type of workholding device commonly used on CNC lathes for securely gripping and holding workpieces during machining operations.

A power chuck is a type of workholding device commonly used in machining operations to securely grip and hold workpieces during turning, milling, drilling, or grinding processes. They are typically used on CNC lathes, machining centers, and other machine tools.

Hydraulic lathe chucks are commonly used in CNC lathes and other precision machining equipment to provide a strong and reliable grip on workpieces, ensuring stability and accuracy during turning, milling, drilling, or grinding processes.

GET A FREE QUOTE